Adopt threespine click processing, so that no hardware is required for furniture assembly.

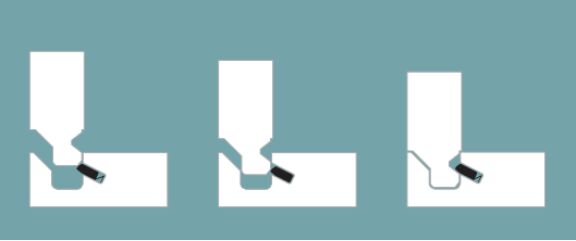

It uses double end tenoner production principle to process click profile (groove) of threespine click furniture, high precision and high efficiency. At the same time,push out the single end tenoner. Double end tenoner have two models.Meet the processing requirements of the structure panels, such as tongue, groove, back board .The middle board is processed by special equipment.A tongue and a groove can also be arranged on a device and selected for use through control. Customers can choose according to the output and click profile.

If the customer small batch production, it is recommended to use one machine and install more than one function shaft,and process the workpiece separately.If the customer have big batch production, it is recommended to use two machine which have 4-6 stations,carry on the continuous processing to the tongue and groove separately, then the single end tenoner to process the single side groove order to increase efficiency.

If the basic connection is needed , the combination of single chain single end tenoner and double end tenoner can be adopted.Single end tenoner main process one side longitudinal groove.Double end tenoner can be selectively processed groove or tongue.It can process one side or two side at the same time.

Suzhou Hotjin Precision Machinery Co., Ltd.

Suzhou Hotjin Precision Machinery Co., Ltd.