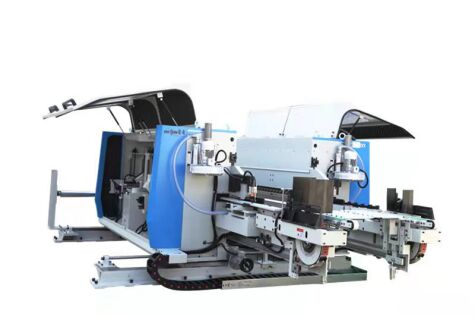

Product description:

We install adjustable pushing device on the left and right two high precision feeding chains of transverse double end tenoner. Ensure the vertical precision of panel and datum edge after processing. The front section has a photoelectric control storage bin,convenient for automatic feeding. According to panel's feature, each station can install jumping cutter, scrape cutter, up and down saw,polishing and so on function shafts, as well as can reserve spacing station.

Main machine technical parameters

|

Equipment name |

Transverse double end tenoner |

|

Technical parameter |

DTH |

|

Working width(mm) |

400-1500/2500 |

|

Working thickness(mm) |

3-25 |

|

Qty of cutter shaft |

6 or 8 |

|

Feeding speed(m/min) |

50 |

|

Power of cutter shaft(KW) |

3/5.5 |

|

Height of working table(mm) |

1000 |

Description: The working width of the panel can be customized if you have special requirements. The maximum width can be 5800mm.

Suzhou Hotjin Precision Machinery Co., Ltd.

Suzhou Hotjin Precision Machinery Co., Ltd.